Rug Making Process

Our rugs are not made by large machines like numerous large blanket and rug makers. We believe in the Hand-Made process. They are made affectionately by hand, with every carpet taking days and at times a long time to finish. The weavers keep up the antiquated routine with regards to utilizing locally sourced wool, making plant-based colours and utilizing small wooden foot-loom that outcomes in heirloom rugs that will endure forever. Here is the procedure of their stunning art.

- Selection of Raw Material

The process of making the rug is initiated with choosing Raw Material, that is sourced from a different material. For the eg-The origin of New Zealand Wool is New Zealand and Mohair Wool is South Africa.

- Herding/ carding/ spinning

In wool herding Process, the plain wool materials and other impurities are moved apart to get the best product and then washed in spring water. Carding process includes cleaning and combing the wool. After Carding the fibres of wool are twisted and drawn to make yarns of specific thickness and this process is known as spinning.

3. Designing Process

In the Designing process, weavers make their design or customize design as per the client requirement. Our Skilled and talented craftsman show most extreme devotion, to make remarkable, high-quality rug of tremendous character, which can coordinate with each stylistic theme and require an even coordinate to global home fashion standard.

4. Dying

The wool can be dyed either by synthetic dyes or natural dyes. Natural dyes are similar as vegetable dyes without the utilization of any synthetics and it’s not as ideal and bright shade as synthetic ones however have smooth texture and effect on the rug. Synthetic dye have bright colours with numerous shades. We normally use Azo- free chemical Dyes or it’s depends upon the client requirement.

5. Ball Making

After dying raw material is rolled to make balls so that weavers can easily tie knots and material is smoothly coming out. The normal knot density of our rugs are 100 & 150 knots every square inch.

6. Weaving

This process is done in a very creative way, it is performed by 3 to 4 weavers depend on the size of the Rug. Rug weaving is finished with the assistance of iron-rod, scissors, yarn balls, levers, comb beater, and so on. The most widely recognized knot thickness of our rugs are 100 and 150 knots for every square inch.

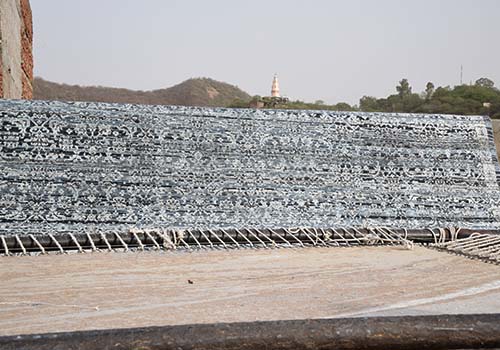

7. Washing

After trimmed, the rug is washed with plain water by using household cleaners to remove germs particles, impurities and to give a natural shine to the material. The rug is then dried out in the sun for 4-5 days.

8. Finishing

The rug ought to be trimmed again to remove unwanted yarn. After vacuum cleaning, it is packed by using packing material for the shipping process.

9. Finished Product.

Now the final product is ready to buy by the customers to enhance the interior of their home space.